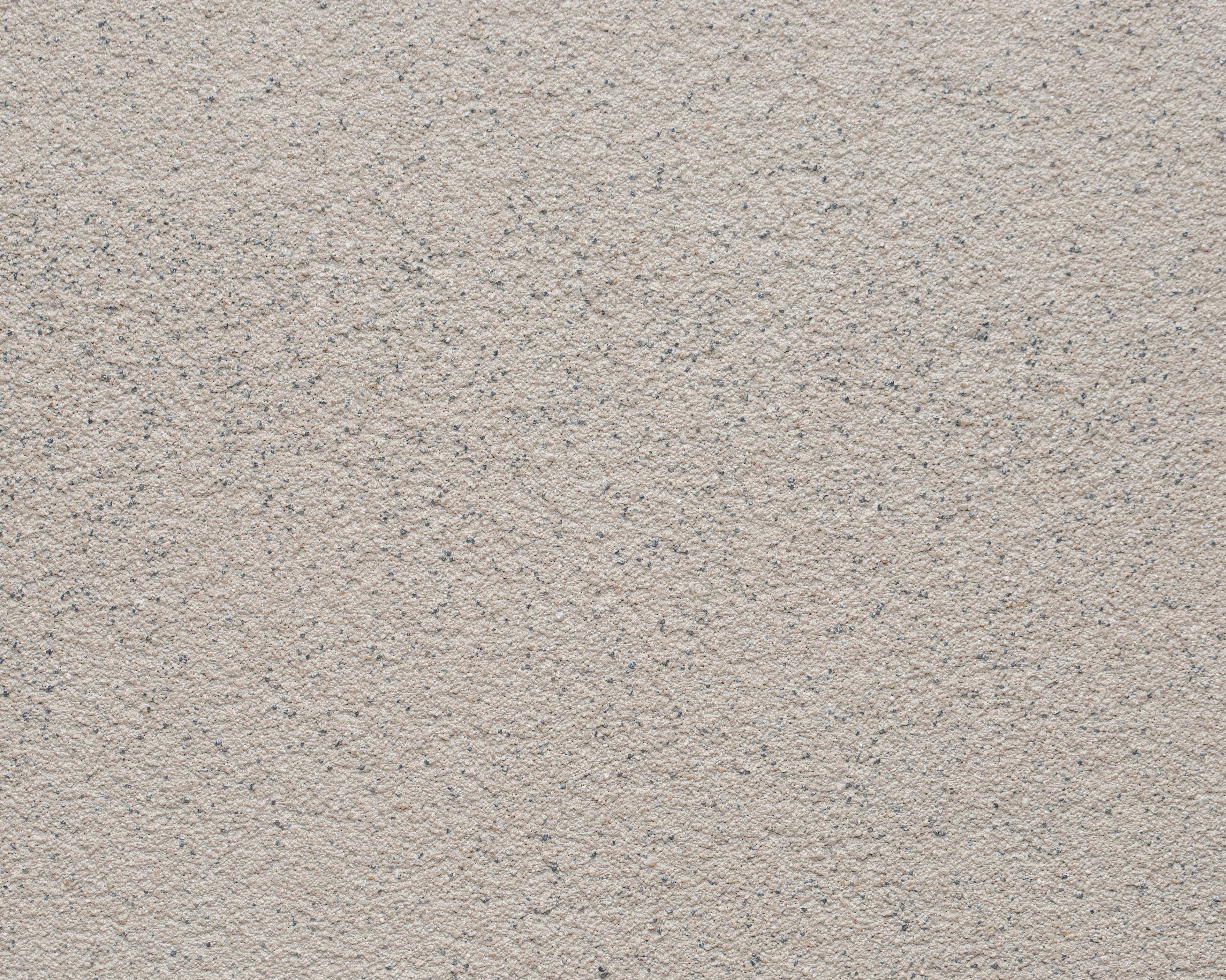

Acratex® Sienna™ Natural is a trowel applied, tintable decorative texture coating producing a uniform fine flecked sand-texture profile with an earthy natural Tuscan look. The coloured granular finish is enhanced with a finish coat of Dulux Venetian® Plaster Matt or Satin Glaze producing a subtle mineral glistening effect to highlight the features of any project.

Re-coat

24 hours

Cleaning materials

Water

Application Tools

Trowel, Hopper Gun

A spread rate of 0.8 square metres per litre is required (approx. 12 m2 per 15L) To ensure colour uniformity and for optimum performance, Dulux recommend a full coating system including a MEMBRANE top coat. For ALL systems the Texture &/or Base Coat should be tinted in accordance with AcraTex Tint Guide to the specified top coat colour (or a colour as close as possible to the specified colour as product and tint rules allow). IMPORTANT: Not all colours are suitable for exterior use. This product data sheets is to be read in conjunction with DULUX specification. Ensure that you have adequate tinted stock to complete the job in one application. All material must be thoroughly cross-mix to ensure tint uniformity. It is recommended to hold a volume of finish material for future maintenance touch-ups.

Practical spreading rates will vary from quoted theoretical figures depending on substrate porosity, surface roughness, overspray losses, application methods and environmental conditions (e.g. wind).

All preparation and painting must conform to AS2311: The Painting of Buildings At Commencement of coating system application, to the substrate it shall be deemed that the Applicator has certified that the surface which the coating/s is to be applied to, is fit to receive the specified coating(s) system.

Do not apply paint if Relative Humidity is above 85% or temperature is within 3°C of Dew Point. Do not apply if the surface temperature is greater than 40°C or below 10°C, or likely to fall below 10°C during the application or drying period. Dry times apply to a single coat at recommended spread rate and at 25°C and 50% Relative Humidity Allow longer times under cool, moist, or still conditions and or when applied at high film builds. Protect from dew, rain and frost for 48 hours when apply at the recommended spread rate. Avoid application in hot, windy conditions or on hot surfaces cool the surface by hosing with water and paint the cool damp surface.

Application techniques should be adjusted to achieve the recommended DFT and finishing standard. To avoid "Picture Framing" of texture topcoats "wet on wet" cutting in & coating technique is recommended or apply multiple coats thinning the first coat. When using Bright Reds, Oranges, Blues and Yellows or where very light (or dark) colours are applied over highly contrasting colours an extra coat maybe required.

The coastal area is considered a marine environment and as such salt potentially can shorten the life of the coating systems. Care needs to be taken to wash down all areas twice. Once to remove surface contaminants, and raise salts to the surface and then secondly to remove these salts. Due to the locality, weather conditions and lag time between applications of the coating system it may require the need to wash again, between coats.

When the Applicator is preparing the site sample for approval he should advise the Project Superintendent if the substrate condition is not of sufficient standard to produce the specified finish.

Where possible avoid dark colours - these will give raise to much higher surface temperature that may cause addition thermal stress and cooling demand to the building envelope and/ or require extra engineering considerations (greater building costs). Consult Dulux on the potential to use InfraCOOL Heat Reflective Coatings. A DULUX warranty can be provided on request, when the FULL AcraTex system including a membrane topcoat/s is applied by a DULUX AcraTex trained applicator, according to specification, & at the specified spreading rates, & to the surface preparation details described in the DULUX AcraTex Specification Manual

The dynamics of the substrate is outside the control of Dulux NZ and as such joint deformation or cracking is excluded from warranty terms. Colour change is a natural part of a coating weathering and is excluded from warranty terms Refer warranty document for full terms and conditions. CEMENT RENDERS PRODUCE FINE CRACKS DURING DRYING AND CONTINUE TO CRACK & MOVE WITH VARIATIONS IN TEMPERATURE. FOR ENHANCED PERFORMANCE USE A HIGH BUILD ELASTOMERIC (FLEXIBLE) COATING. DULUX RECOMMENDS THE USE OF DULUX ACRASHIELD ADVANCE.

Fungi and Algae can exist on virtually any surface (even glass) provided the right conditions for growth are met. Visible growth on painted surfaces is typically caused by contaminants present together with the presence of high enough levels of moisture to support growth. Agents in paints become ineffective where they cannot “touch” the growth source (eg where growth emanates from deposits on the film). Additionally the active agents are “consumed” in the process such that protection is time limited where conditions support ongoing growth performance is greatly improved with the inclusion of a membrane Top coat like Dulux AcraTex AcraShield Advance, Elastomeric 201 or AcraSkin.

The exterior texture coatings should be cleaned on a regular basis. This will help maintain your overall aesthetic appearance and preserve your AcraTex Texture coating system. Cleaning once every year will remove light soil as well as grime and airborne pollutants refer Dulux AcraTex Care & Maintenance Guide.

SURFACTANT LEACHING FROM EXTERIOR WATER-BASED COATINGS Occasionally amber, clear or white spots/streaks are seen on a newly painted surface within the first few weeks after application. They usually appear after light rain or overnight dew and generally located in sheltered areas or areas with limited sun exposure. Under normal conditions surfactant contained in the tinted paint colour is slowly leached to the surface and washed away by rain leaving no trace and is a normal part of drying of any exterior water-based paint. Under certain atmospheric conditions and these surfactants leach or migrate to the paint surface, is concentrated forms and leaves clear or white deposits upon drying. These conditions include cool or humid weather or painting cold substrate and in most cases these marks on the wall surfaces are more noticeable on dark colours, such as browns or dark greens, etc.. The clear/white surfactants that have migrated to the wall surface areas will cause no down grading nor performance changes or long term durability concerns of the paint films integrity and unfortunately have become an appearance issue instead. They easily removed from the paint film within a week or so of their appearance by washing with warm water & commercial grade detergent or via Nifti or Spray'n'Wipe followed by rinsing with fresh clean water. Under severe conditions they may reappear once or twice until all the surfactant has been removed. It will be less noticeable each time, and can be removed in the same manner as before.

Relative to Project Substrate and Specified Finish - refer to Project Specific Duspec Specification and Acratex® Substrate Guide.

Product should be thoroughly mixed before use. Refer to the Dulux Acratex Application Manual for detailed instructions.